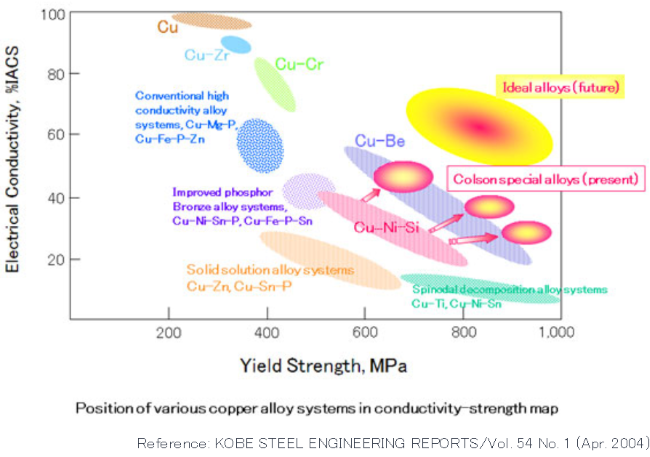

There are no alloys anywhere on the market that can compare with our revolutionary new type of environmentally-friendly NC alloy, which contains nickel, silicon and chromium, but is beryllium-free.

We now supply our NC alloy material to one of Japan’s Big Three auto manufacturers, and another of the Big Three is evaluating the alloy with hopes that its use will contribute to environmental sustainability. Also, one of the largest die cast machine makers in Japan has been conducting tests on the NC alloy because it is well-suited for plunger tips.

Additionally, one promising application for the NC alloy is for moving parts that are used under heavy conditions, such as in Formula 1 engines and for brake material due to the alloy’s high hardness and conductivity and its excellent wear resistance. In fact, our NC alloy was used as brake material in an amusement park ride in Tokyo, and demonstrated a life span of more than 10 times longer than conventional brake material!

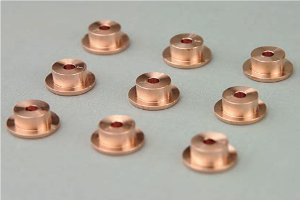

Because of its superior characteristics, including high electrical conductivity and hardness, NC alloy has been used for many other, small-to-large applications such as welding LED crystal oscillator parts to lids for cell phones, resistance welding large anchors for ships, and so on.

FEATURES:

▸Wear resistant

▸Long lifespan

▸Electrical conductive

▸Thermal conductive

▸High hardness

MAIN APPLICATIONS:

▸Plunger tips

▸Injection and blow-mold fabrication material

▸High-performance engine parts

▸High-performance brake material

Both of our NC25 and NC50 alloys boast uniform high hardness, tensile strength and yield strength, as well as high electrical conductivity. NC25, with it’s high tensile strength of 1 giga Pascal (145 ksi), is well-suited for machinery parts. NC50 features not only excellent electrical conductivity, but also superior thermal conductivity, savings in lubricant cost, shorter holding time, and quality improvement in die cast production.

NC25 (CuNiSiCr System)

CHEMICAL COMPOSITION:

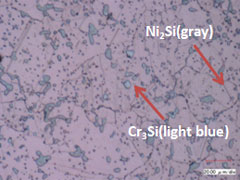

Ni: 6.5~8.8 mass% | Si: 1.5~2.5 mass% | Cr: 0.3~1.3 mass% | Cu: bal.

TYPICAL MECHANICL PROPERTIES (as aged)

Tensile strength (MPa): 820-1000

0.2% Yield strength (MPa): 650-980

Elongation: 2%-10%

Hardness (HBW 10/3000): 250-270

TYPICAL PHYSICAL PROPERTIES (as aged)

Electrical Conductivity (IACS%): 27

Thermal Conductivity (W/m・K): 130

Specific Heat (J/g・K): 0.40

Density (g/cm3): 8.7

NC50 (CuNiSiCrSn System)

CHEMICAL COMPOSITION:

Ni: 1.7~2.5 mass% | Si: 0.3~0.7 mass% | Cr: 0.5~1.2 mass% | Sn: 0.1~0.3 mass% | Cu: bal.

TYPICAL MECHANICL PROPERTIES (as aged)

Tensile strength (MPa): 650-850

0.2% Yield strength (MPa): 600-800

Elongation: >9%

Hardness (HBW 10/3000): >90

TYPICAL PHYSICAL PROPERTIES (as aged)

Electrical Conductivity (IACS%): 40-50

Thermal Conductivity (W/m・K): 180

Density (g/cm3): 8.7

※We conduct these manufacturing and treatment processes on both our NC25 and NC50 alloy material:

▸Melting and Durville Casting to eliminate internal defects

▸Hot forging or extrusion is conducted to refine and and ensure uniform dispersion of Ni2Si compounds

▸Solution treatment enables rapid quenching without cracking

▸Aging to facilitate precipitation hardening and increase electrical conductivity